Jan. 15, 1919, is a date that will forever live in infamy for the residents of Boston, Massachusetts. It was an unseasonably warm day, and witnesses in the area recalled hearing shots like gunfire just after noon. All of a sudden, a 2.3-million-gallon wave of molasses flooded down Commercial Street in the city's North End. After the sticky deluge subsided, property was severely damaged, 21 people died and 150 bystanders were injured.

How could what became known as the Boston Molasses Flood happen?

Advertisement

The Purity Distilling Company was a manufacturer of rum and industrial alcohol in Boston's North End. In 1915 they had erected a massive steel tank, 52 feet (15.9 meters) tall, 90 feet (27.4 meters) across, and able to hold 2.5 million gallons (9.5 million liters) of molasses, which was a prime ingredient for their enterprise. Later investigation found that the tank wasn't structurally sound to begin with — in fact, it had even been quickly painted brown to hide the fact that it leaked molasses constantly.

Just before the disaster, the tank had been filled close to capacity with a recent shipment of molasses. Then, on Jan. 15, 1919, just a year before Prohibition would go into effect, the tank ruptured.

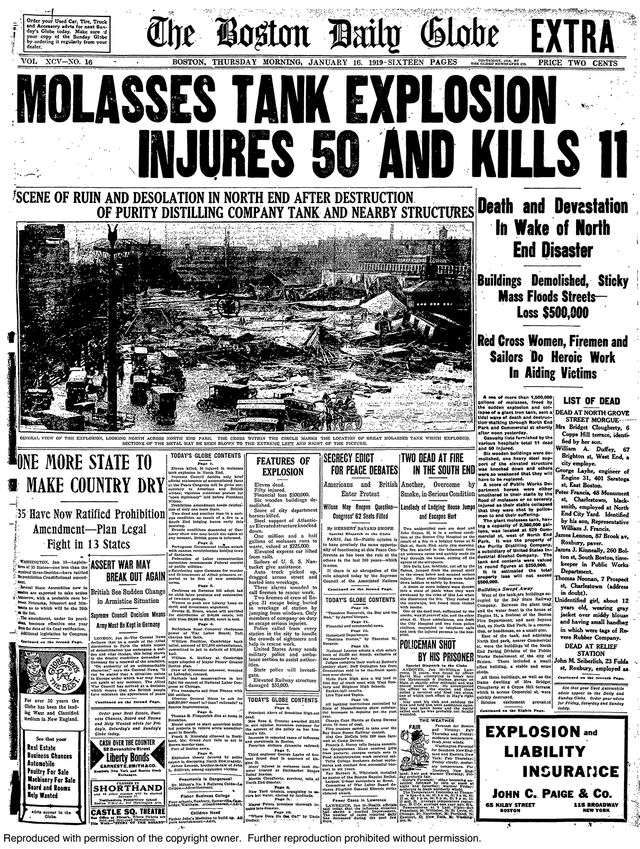

Initial reports suggested that anarchists might have blown the massive tank owned by the Purity Distilling Company. The Jan. 16 edition of "The Boston Globe" suggested that an internal explosion could have been the culprit. But the reason for the tank's explosion was much more insidious: reckless craftsmanship. With little in the way of regulation at the time, the Purity Distilling Company tossed together its molasses tank without the benefit of anyone qualified to design so massive a tank.

"It's a common misconception that the tanks exploded," says Jamie Windon, owner and co-founder of Lyon Distilling in Maryland, via email. "The tanks actually broke, because at the time they were made of steel that was too thin, reportedly below standards, even for the time, and the sheer weight of over 2 million gallons of molasses was far too much to bear, eventually causing the tank to fatigue and break, spilling ungodly amounts of molasses out of the warehouse and into the streets."

Since the tank wasn't a building or a bridge, there was no regulatory agency responsible for inspecting or regulating it.

Jesse Brenneman, co-founder of the Deacon Giles Distillery in Massachusetts explains why a flood of this nature wouldn't even be possible today. "Modern day distillers store molasses in small totes of about 275 gallons each, or in stainless steel tanks at larger volumes," he says via email.

"Stainless steel has many wonderful properties," continues Brenneman, "which include an extreme resistance to rust or deterioration and incredible high strength and rigidity. And smaller 275 gallon totes clearly do not present a flood risk. Tanks are well vented, often with two or more pressure and vacuum relief devices. Additionally, most very large outdoor storage tanks also include secondary containment —a trough or bowl built around the base of the tank that can hold it's entire contents should it leak or rupture."

Advertisement